The definition of white porcelain, incorporating current academic advancements, can be established as follows: porcelain fired at temperatures exceeding 1200°C. If no slip coating is applied, both the body and glaze must contain less than 1% iron oxide. For white porcelain with slip coating, the body may contain slightly higher levels of iron oxide and other coloring elements, but a transparent glaze must be applied externally. Additionally, certain variations in hue are permissible. For instance, glaze colors exhibiting a bluish or yellowish tinge within the spectrum of white do not preclude classification as white porcelain.

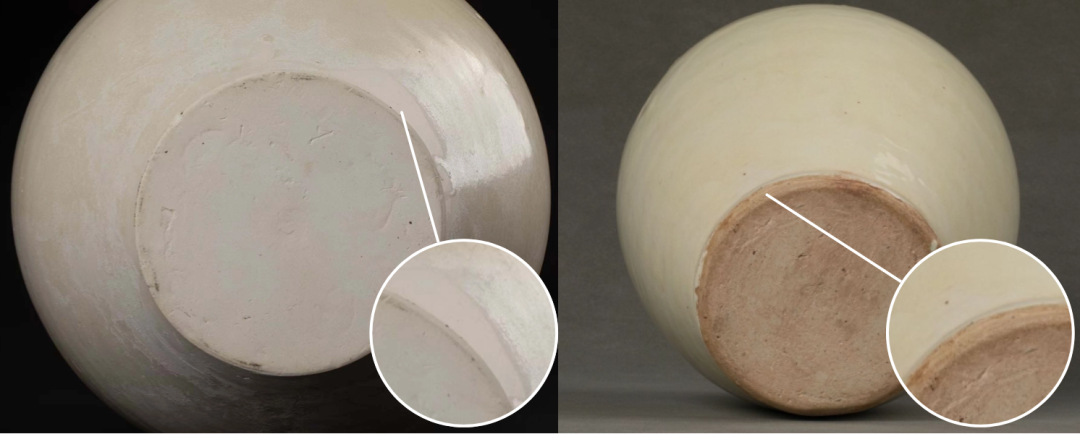

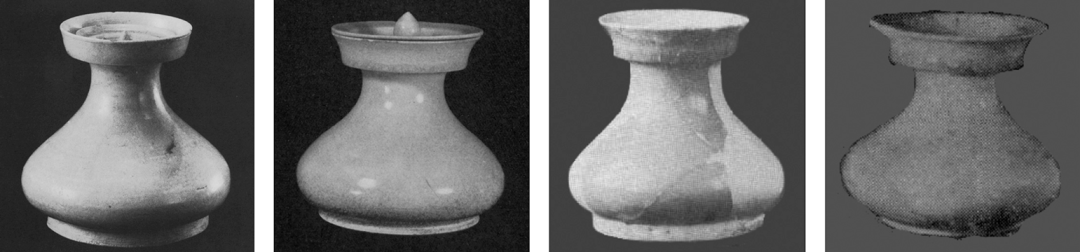

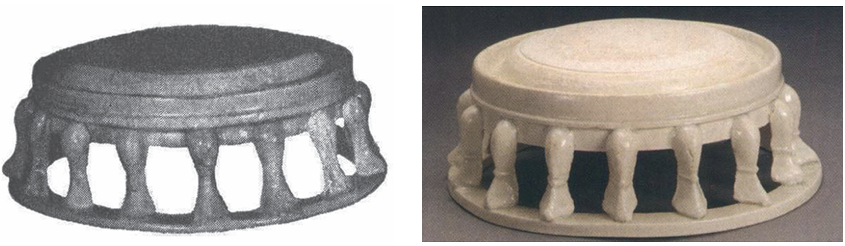

Comparison of White Jars from Gongxian Kiln with and without Slip

White porcelain originated from celadon yet evolved into a distinct tradition. Its development stemmed from the evolution of celadon, primarily manifested through two technical innovations: the use of slip decoration and the emergence of lead-glazed porcelain.

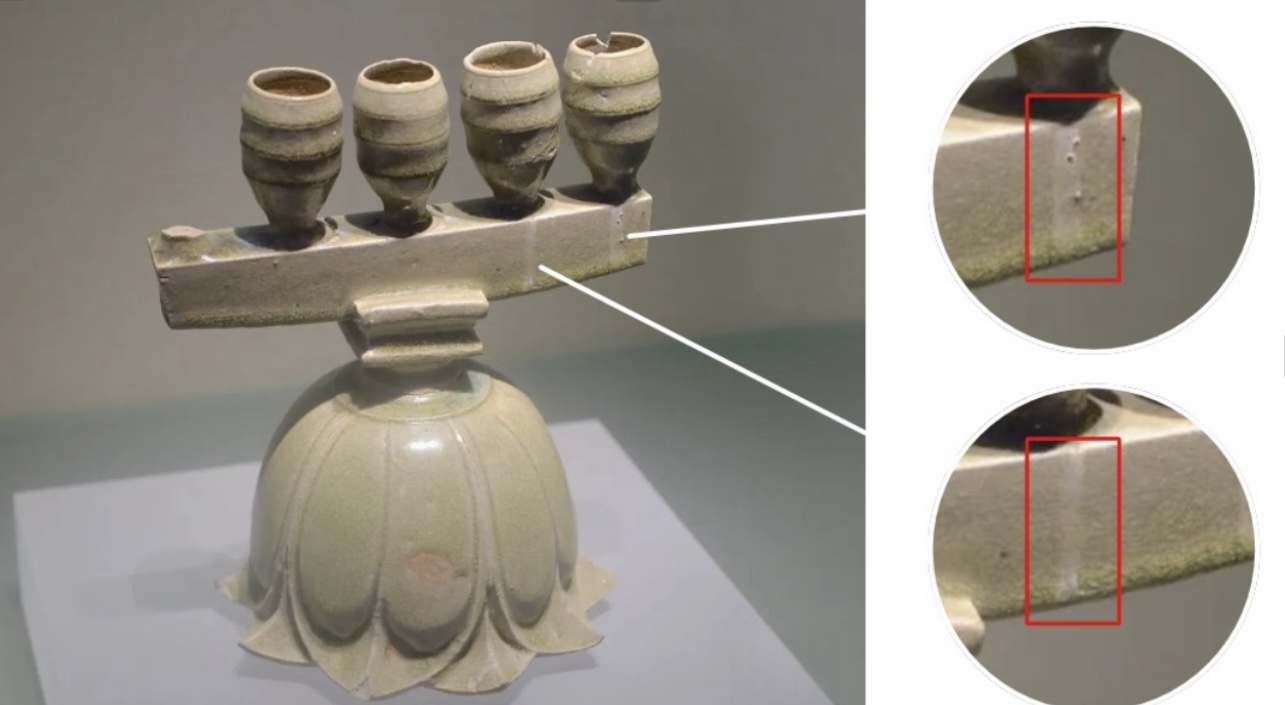

First is the use of cosmetic clay.Slip is a specially processed, fine-grained porcelain clay or a slurry made from carefully selected high-alumina, low-iron raw materials. Initially widely used on celadon ware, its purpose was to refine the coarse surface of the body, resulting in a smooth and uniform glaze after firing. This technique first emerged in southern China. For instance, the Hongzhou Kiln in Fengcheng, Jiangxi, began using slip glaze as early as the Eastern Wu period of the Three Kingdoms era. By the late Southern Dynasties, slip glaze was further employed to enhance glaze coloration, producing exquisite high-end vessels. Examples include lotus-pedestal candlesticks featuring flowing white slip glaze, which rendered the entire surface uniformly smooth and produced a delicate, pale green-blue glaze effect.

Celadon Lotus-Pedestal Candlestick Unearthed from the Tomb of Li Bi of the Northern Wei Dynasty

In their quest to enhance the quality of celadon, ancient kiln workers directly spurred the emergence of white porcelain. This technological evolution began with the high aluminum, low silicon, and low iron-titanium characteristics of northern porcelain clay, which provided natural advantages for both body and glaze production, laying the raw material foundation for white porcelain. Subsequently, iron content in the body and glaze was reduced through washing, while potassium content was increased by adjusting the mixture ratio, forming an “alkaline calcium glaze.” Finally, after enhancing the whiteness of the body, colorless transparent glazes were fired in the reducing atmosphere of bun kilns, yielding a pearly white hue with a faint bluish tint.

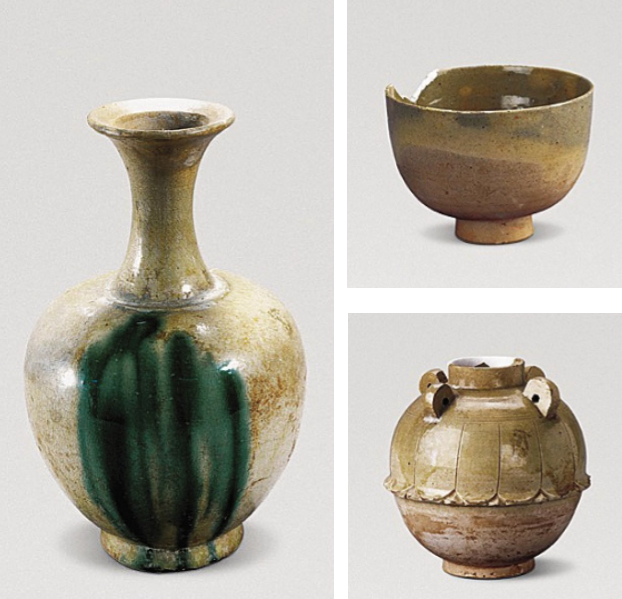

Another important technical clue lies in the firing of lead-glazed porcelain.In fact, many so-called early white porcelain products mentioned in brief reports are actually ‘white-glazed pottery’ or ‘white lead-glazed porcelain’. Take, for example, the white-glazed ware and white-glazed green-decorated ware unearthed from the tomb of Fan Cui in Anyang, Henan, dating to the sixth year of the Wuping era of the Northern Qi dynasty (575 AD) in 1971. These artifacts were made from high-silica, high-alumina porcelain clay bodies. After being bisque-fired at temperatures above 1200°C to achieve porcelainization, they were coated with lead glaze and subjected to a secondary firing at low temperatures between 700–800°C. Despite their high body whiteness and glaze transparency resembling white porcelain, scientific analysis confirms their fundamental nature as low-temperature lead-glazed pottery. These vessels exhibit distinct transitional characteristics. Through refinements in body-glaze formulations, firing temperatures and atmospheres, and loading techniques, they ultimately facilitated the evolutionary shift from celadon and early white porcelain to mature white porcelain.

White-Glazed Pottery Unearthed from Fan Cui's Tomb in Anyang, Henan, Dating to the Sixth Year of the Wuping Era of the Northern Qi Dynasty (575 AD)

1. White-Glazed, Green-Decorated Long-Necked Vase 2. White-Glazed Bowl 3. White-Glazed Four-Handled Jar

In general, from the very beginning of white porcelain production, manufacturers adopted techniques refined from celadon to achieve their goals. One approach involved directly improving the quality of the clay body without applying slip, resulting in a naturally pure white hue. The other method employed white slip to conceal or modify the original color of the clay body.

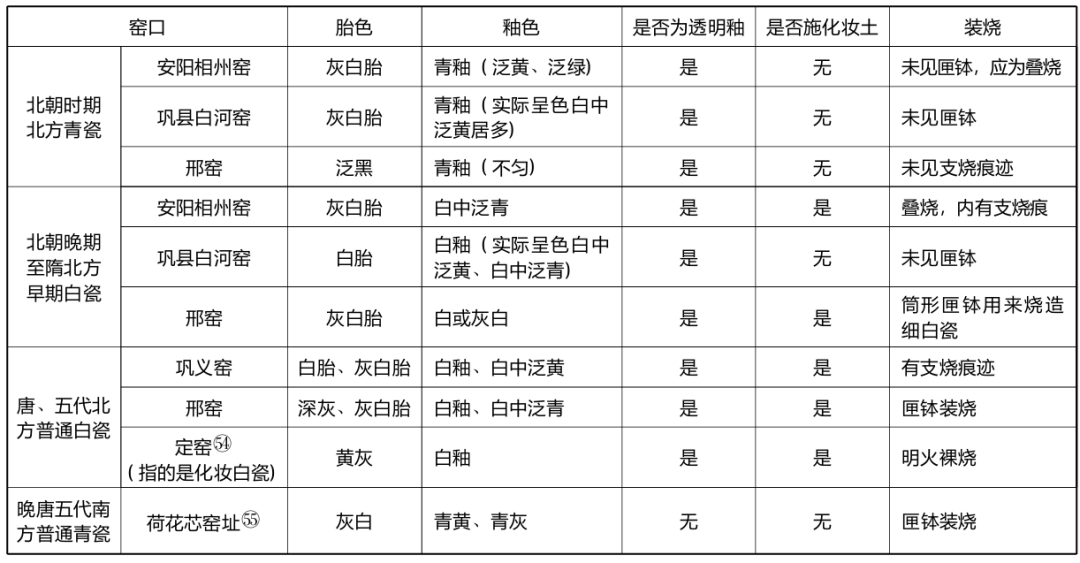

Comparative Study of Northern Celadon, Early White Porcelain, and White Porcelain from the Northern Dynasties to the Late Tang and Five Dynasties Periods, and Southern Celadon from the Late Tang and Five Dynasties Periods

From the Sui Dynasty to the mid-to-late Tang Dynasty, glazed white porcelain (coarse white porcelain) and unglazed white porcelain (fine white porcelain) appeared to be two relatively parallel systems. Products of the same or similar types could be found in major kilns, with both methods employed simultaneously.

However, as white porcelain matured and evolved, the distinction between glazed white porcelain (coarse white porcelain) and unglazed white porcelain (fine white porcelain) became increasingly pronounced from the late Tang Dynasty to the early Northern Song Dynasty.First, represented by Ding Kiln, which produced fine white porcelain with a fine, white body and a slightly translucent white glaze. Second, represented by the Cizhou Kiln system, which produced coarse white porcelain with a relatively coarse body and darker body color, coated with white slip, produced in numerous kilns across the vast northern regions.

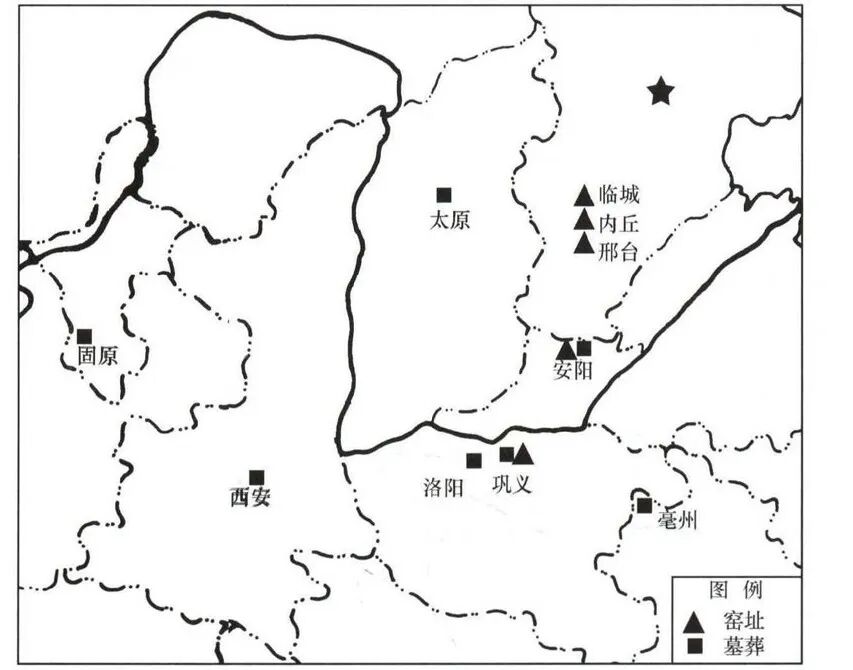

Overview of White Porcelain in the Sui Dynasty

The production of Sui Dynasty white porcelain was primarily concentrated in two northern regions: the Xing Kiln in southern Hebei (present-day Neiqiu and Lincheng areas of Xingtai) and the Xiangzhou Kiln in northern Henan (near present-day Anyang) within Northern Region I, along with the Gongyi Kiln in central Henan (represented by the Baihe Kiln). These three kiln areas collectively formed the production pattern for Sui Dynasty white porcelain. In terms of product characteristics, the Xiangzhou and Gongyi kilns pursued the purity of the body and glaze itself, refraining from applying slip. In contrast, the Xing Kiln expanded the output of coarse-grained white porcelain through slip application techniques while also producing a small quantity of “translucent white porcelain,” demonstrating a technical breakthrough.

Schematic Map of Kiln Sites and Burial Locations for White Porcelain Unearthed from the Sui Dynasty

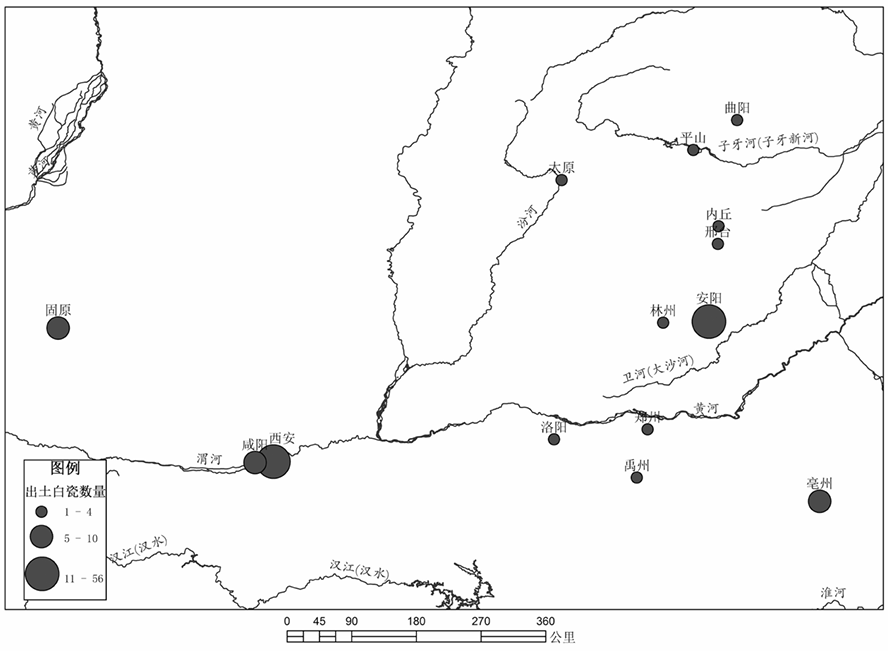

Distribution Map of White Porcelain Unearthed from the Sui Dynasty

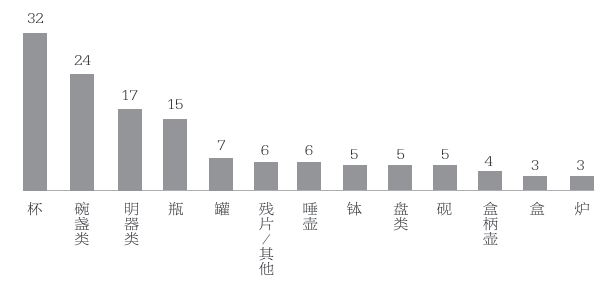

Based on white porcelain unearthed from tombs, common white porcelain forms during the Sui Dynasty include cups, bowls and cups, funerary objects, vases, jars, and 13 other types.

Statistical Chart of Unearthed Sui Dynasty White Porcelain

White Porcelain Spittoons Unearthed from Sui Dynasty Tombs

1. Excavated from the Tomb of Dugu Cang and His Wife

2. Excavated from the Tomb of Lü Wu

3. Excavated from the Tomb of Li Chun and His Wife

4. Excavated from the Tomb of Qu Ju

1. Excavated from Tomb No. 8 at Zhidu Village

2. Unearthed from the Tomb of Li Yu

3. Discovered in the Tomb of Zhang Cheng and His Wife

4. Unearthed from Sui Dynasty Tomb 2004YKJM4 at Jiulong Mountain, Guyuan

5. Excavated from the Grand Market Site of the Han-Wei City in Luoyang

1. Excavated from Tang Dynasty Tomb M172 at Baisha

2. Excavated from Su Tongshi's Tomb

1. Excavated from Li Yu's Tomb

2, 3. Excavated from Li Jingxun's Tomb

4. Collection of Tianjin Museum

Xiangzhou Kiln

The earliest ceramics from the Xiangzhou Kiln were predominantly coarse celadon of inferior quality. Subsequently, kiln sites widely adopted techniques to reduce iron content in both the body clay and glaze. By decreasing the proportion of iron, the body color significantly lightened and the glaze became more transparent, ultimately forming a translucent glaze with a faint bluish tint. This technological innovation marked the evolution of celadon toward higher quality, driving the gradual differentiation of celadon products into coarse and fine categories from the late Northern Dynasties to the Sui Dynasty. The fine-grade celadon approached the characteristics of white porcelain in both body and glaze quality. This technique not only directly influenced the production of early fine white porcelain at the Xiangzhou Kiln but also established the tradition of “white body with transparent glaze.” This laid the foundation for the subsequent development of northern white porcelain (such as that from the Gongyi Kiln), demonstrating its pivotal role in bridging past and future advancements in ceramic technology.

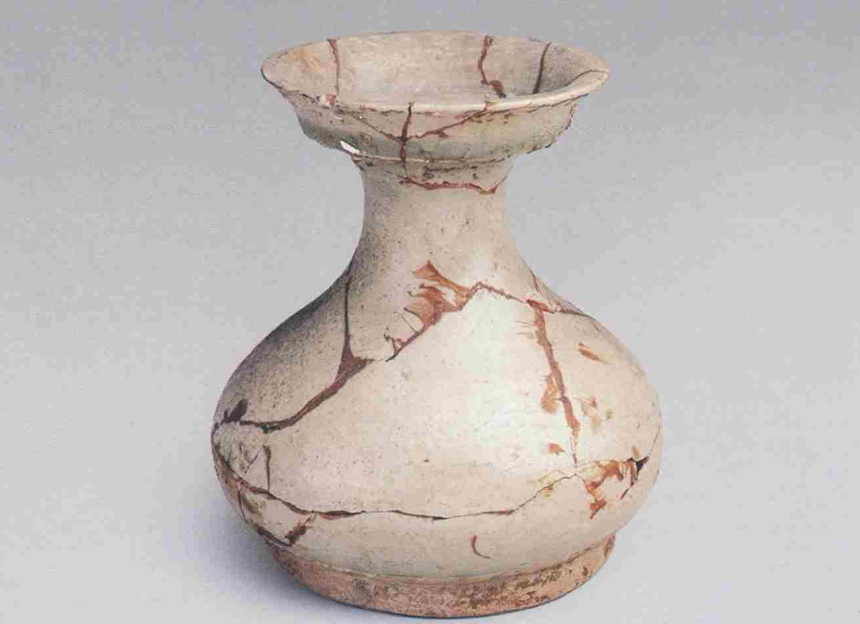

Xiangzhou Kiln Sui Dynasty White Porcelain

Unearthed from Xiangzhou Kiln in 2006

1. Long-necked Vase

2. Flanged-rim Vase

3, 4. High-footed Cups

White-Glazed Three-Legged Basin

Unearthed from the Tomb of Zhang Sheng in Anyang

Height: 4.5 cm

Unearthed from the Tomb of Zhang Sheng in Anyang

Height: 5 cm

Sui Dynasty Tomb Unearthed at Xiaotun, Anyang

Sui Dynasty Tomb Unearthed at Xiaotun, Anyang

Sui Dynasty Tomb Unearthed at Xiaotun, Anyang

Sui Dynasty Tomb Unearthed at Xiaotun, Anyang

Christie's New York, 2015

The Golden Years: Part IV of the David T. Y. An Collection

Sui Dynasty, Celadon-Glazed Long-Necked Vase

Height: 23.5 cm

Sold for: 8,125 USD

2016 Christie's Hong Kong

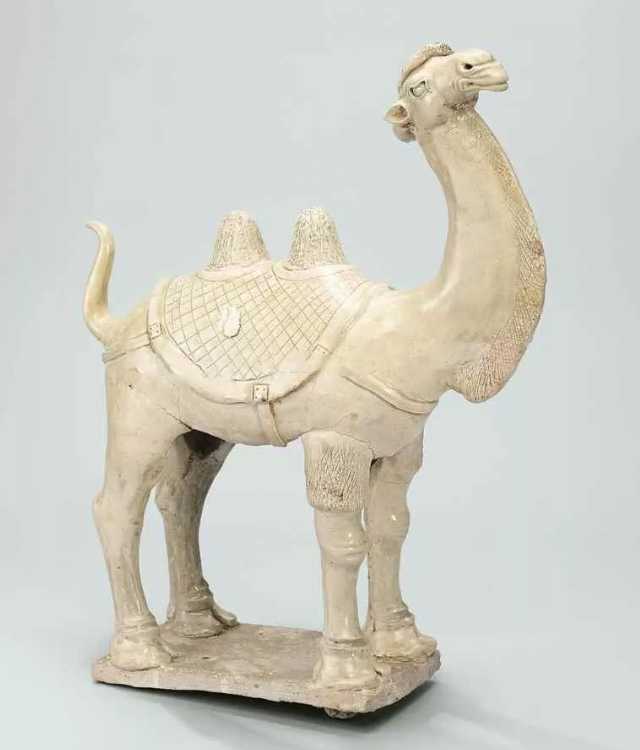

Sui Dynasty White-Glazed Camel

Height: 47 cm

Sold for: HKD 112,500

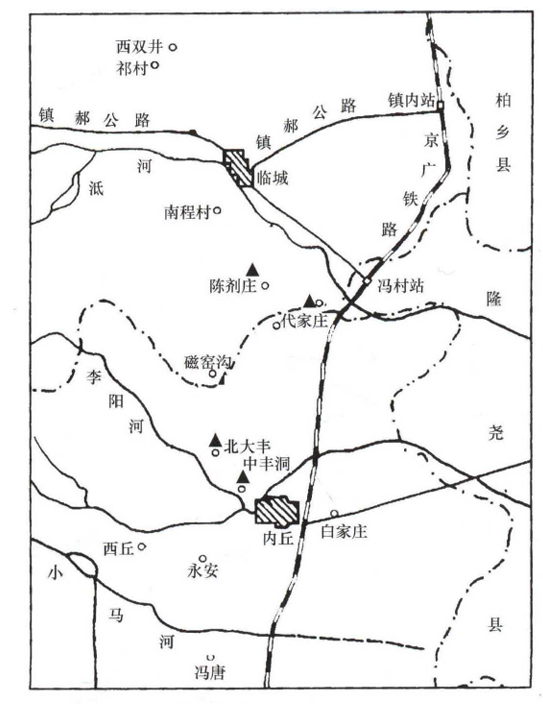

Xing Kiln

Excavated from the Shunde Road Kiln Site, Xingtai, 1997

Sui Dynasty Xing Kiln Flared-Mouth Vase

Collected from the Chengguan Kiln

Excavated from the Xingtai Shunde Road Kiln Site

Translucent White Porcelain Cup Unearthed from the Tomb of General Su Tongshi in Xi'an

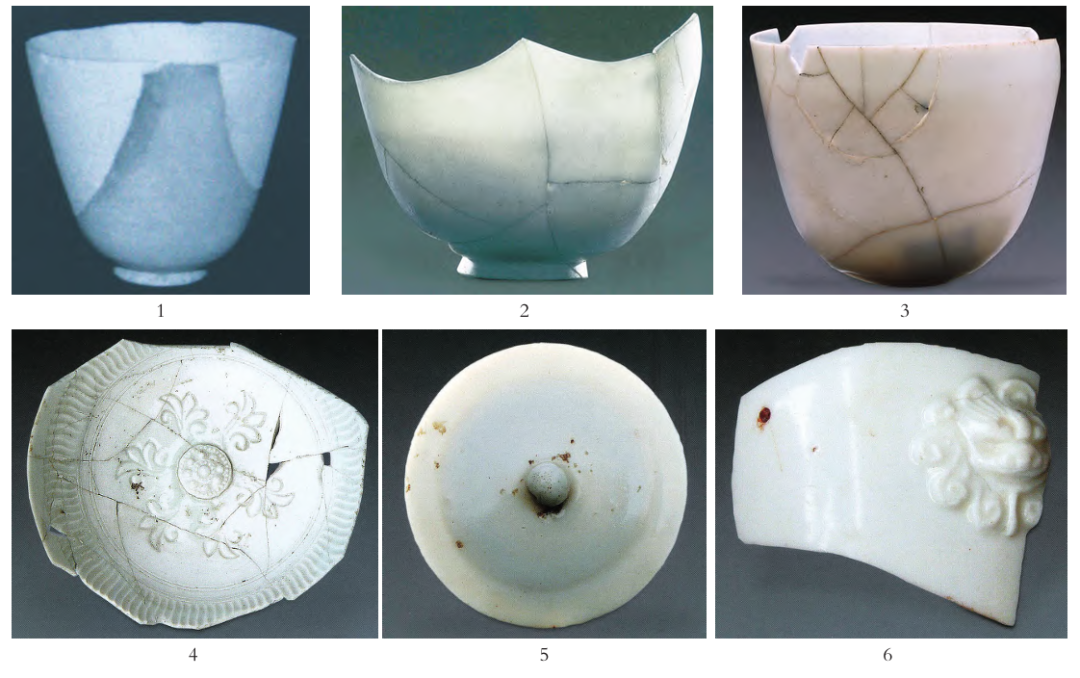

Fine White Porcelain from the Sui Dynasty Unearthed at Xing Kiln Site

1–3. Deep-bellied cups with flared mouths

4. Bowl with applied and incised decoration

5. Lid

6. Fragment of an applied-decoration jar

Unearthed from the Xing Kiln Site in Neiqiu

Sui Dynasty Fine White Porcelain Bowl

Roughly Decorated White Porcelain Bi Yong Inkstone

Unearthed from the Beiyao Site, Xiguan, Neiqiu, 1991

Fine white porcelain parrot-shaped cup

Unearthed from the Beiyao site in Xiguan, Neiqiu, 1988

Fine white porcelain figurines unearthed from the Xing Kiln site in Neiqiu, dating to the Sui Dynasty

Harvard Art Museums, United States

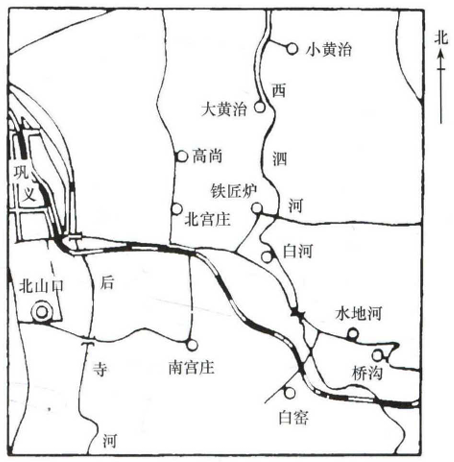

Gongyi Kiln

Currently, two kiln sites in the Gongyi area have been confirmed as producing white porcelain during the Sui Dynasty: the Huangye Kiln and the Baihe Kiln. White-glazed porcelain from the Huangye Kiln during the Sui Dynasty is extremely rare, consisting mainly of small vessels such as bowls and cups. These pieces feature thin, finely textured bodies with glazes that are white or white with a bluish tint. The Baihe Kiln was one of the primary Sui Dynasty production sites for white porcelain. Its wares mainly included cups and bowls, featuring fine white bodies and glazes that were generally white with a bluish tint. Consistent with the Sui Dynasty's Xiangzhou Kiln, Sui Dynasty white porcelain from the Gongyi region was also primarily characterized by the production of fine white porcelain with white bodies and transparent glazes.

Distribution Map of Gongyi Kiln Sites

Based on site surveys and excavated specimens, both the Baihe Kiln and Beiguanzhuang Kiln sites yielded finely crafted translucent white porcelain. The forms comprised two types: open-mouthed deep-bellied cups and open-mouthed deep-rimmed bowls. However, the foot rims were made of ordinary porcelain clay.

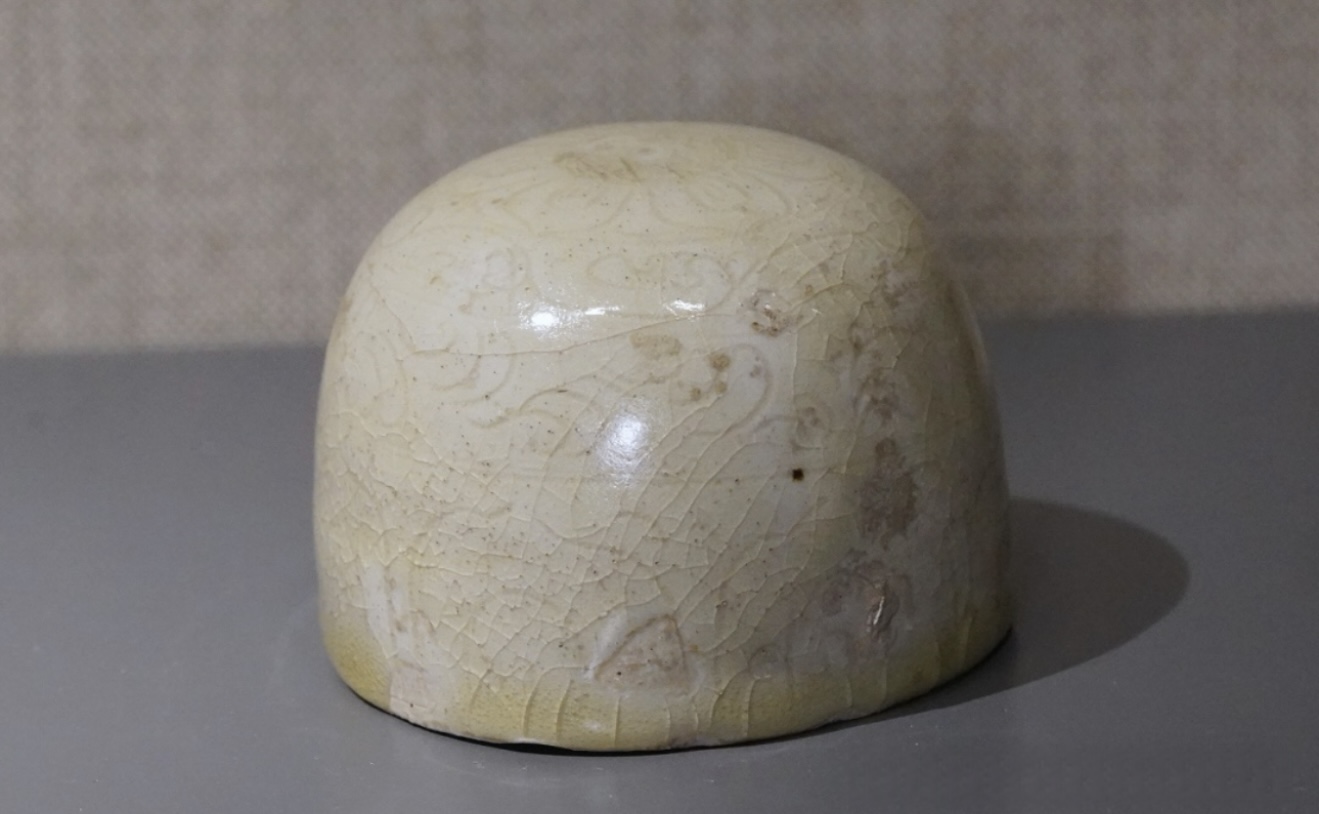

A translucent cup made of fine white porcelain from the Sui Dynasty unearthed at the Gongxian Kiln Site

Unearthed from the Tomb of Sui Hulu Che in Taiyuan, Shanxi

The Ashmolean Museum, University of Oxford, UK

Unearthed from the Tomb of Li Jingxun of the Sui Dynasty in Xi'an, Shaanxi

Sui Dynasty Gongyi Kiln White-Glazed Decal-Decorated Porcelain Plate

Collection of Shaanxi Museum of Archaeology

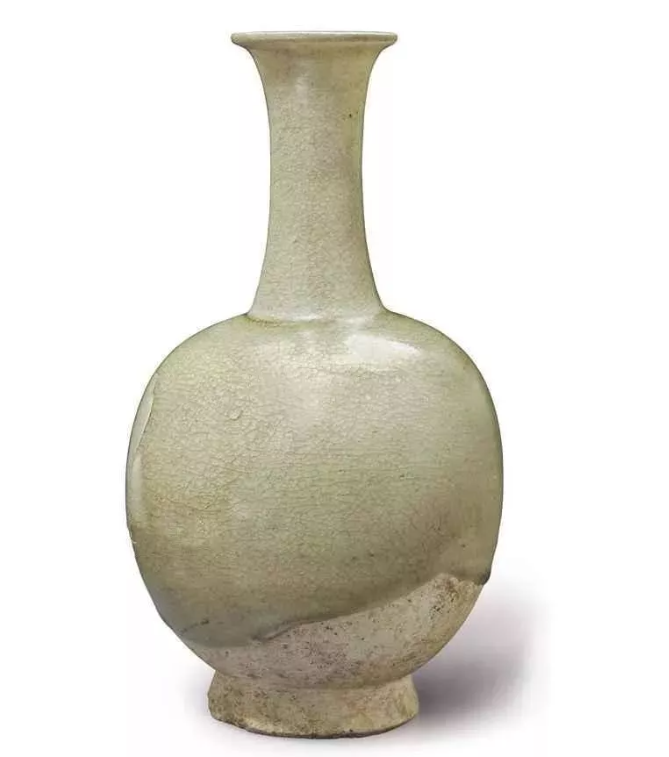

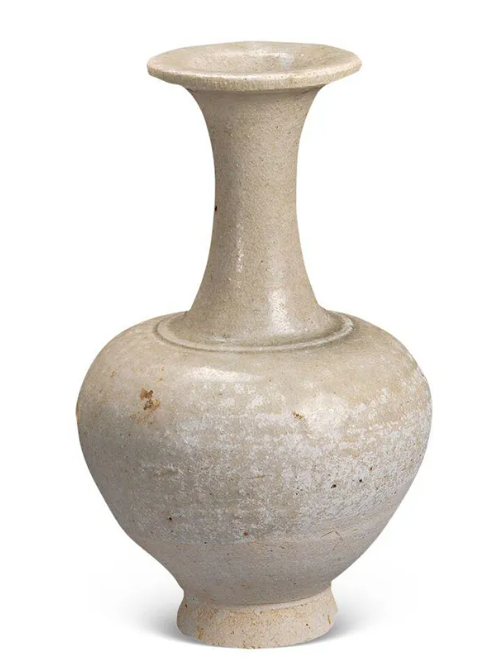

Sui Dynasty Gongyi Kiln White Porcelain Vase

Collection of Shaanxi Museum of Archaeology

Sui Dynasty White-Glazed Plum-Shaped Vase from the Gongyi Kiln

Shanxi History Museum Collection

References

[1] Shen Wenxi. Treasures of Sui Dynasty Ceramics: Fine Pieces Unearthed from the Sui Tomb at Xiaotun, Anyang [J]. Popular Archaeology, 2021, (05): 44-54.

[2] Li Xin. Production, Circulation, and Consumption of White Porcelain in the Sui Dynasty [J]. Bulletin of the Palace Museum, 2021, (12): 27-39+135.

[3] Ren Zilu. An Examination of Refined White Porcelain in the Sui Dynasty [J]. Cultural Relics Review, 2022, (02): 57-67.

[4] Wang Yan. A Brief Discussion on the Emergence and Decline of Xing Kiln White Porcelain [J]. Collecting, 2023, (12): 116-121.

[5] Cui Si. A Study on the Forms of Tang Dynasty Xing Kiln White Porcelain [D]. North China University of Technology, 2020.

[6] Deng Meige. A Brief Discussion on Early Northern White Porcelain [J]. Northern Cultural Relics, 2021, (02): 76-85.

[7] Shen Wenxi. Treasures of Sui Dynasty Ceramics: Fine Pieces Unearthed from the Sui Tomb at Xiaotun, Anyang [J]. Popular Archaeology, 2021, (05): 44-54.

[8] Wang Rui. Archaeologically Discovered White Porcelain of the Sui Dynasty [J]. Bulletin of Archaeology, 2010, (02): 434-453.